RFID System for Dairy Industry

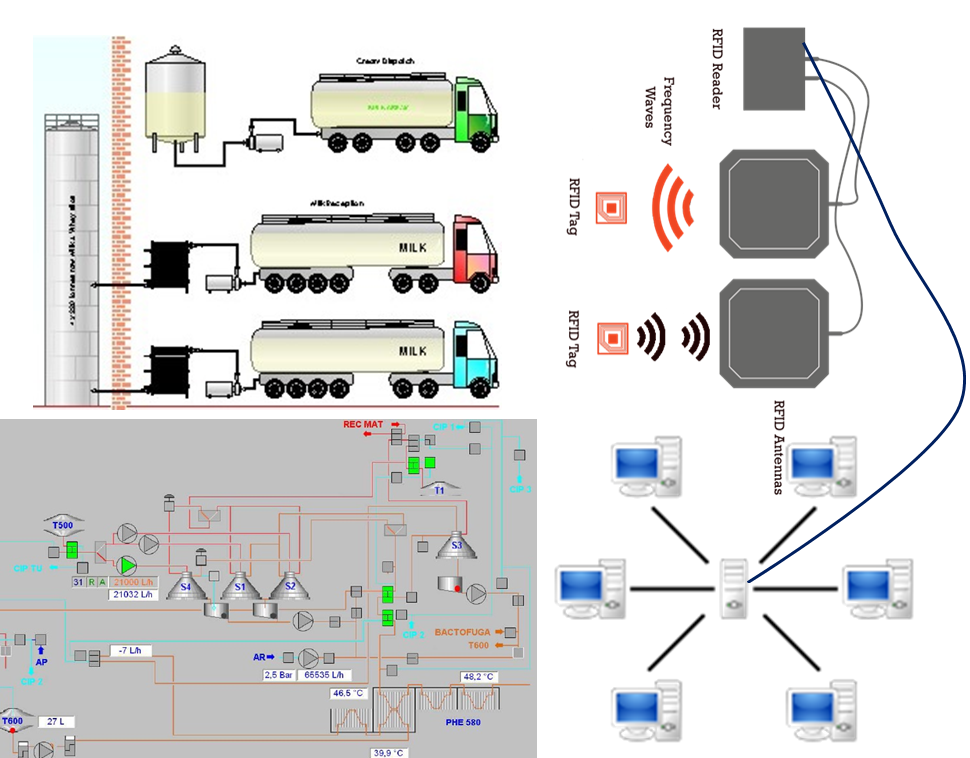

While our product 'fleeton' tracks dairy vehicles outside the campus, our RFID System (Radio-Frequency Identification) product helps track dairy vehicles, once they enter into the dairy campus. Maintaining an efficient production schedule is key to dairy operations and our RFID product is very handy to helping with it.

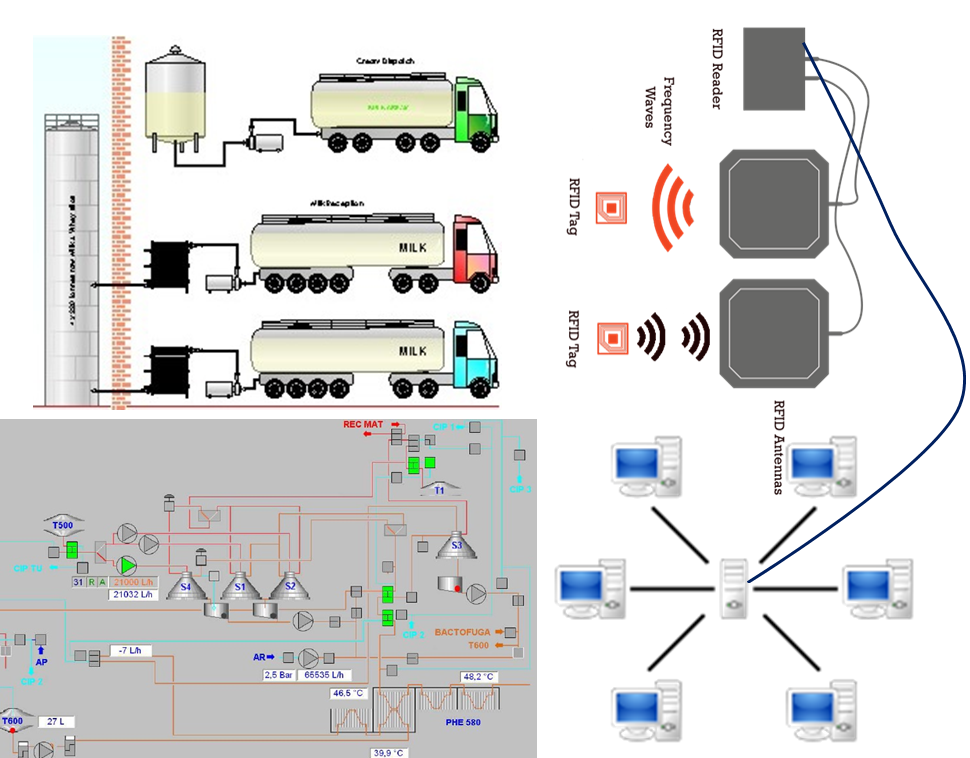

The milk tankers go through various stages of its dairy campus in-to-out cycle. Our RFID System logs the data about when the milk tanker comes in and goes out of the dairy plant campus. The automatic identity of milk tankers could be linked with weighing bridge which prevents from manual error for logging tanker's number plate vs. its weight. The same tanker ID could be linked with the RMRD Lab report data- whether the milk inside the tanker maintains the quality standard and whether it is acceptable for the further LMP cycle (Liquid Milk Processing Cycle) or not. Further, the tankers' automatic identification takes place at the unloading-bay where there are high chances of manual error. The bay's data could be directly rendered into the SCADA system for managing Milk Unloading Plant. And then the CIP (Cleaning-in-Place) compliance could be automatically managed and taken care of, whether the tanker went for CIP after unloading or not.

With the help of this system, real-time monitoring of tankers on various parameters could be done. For example, tankers which are inside the dairy plant campus but are remaining for weighing, tankers which are inside the dairy plant campus but are remaining for unloading, tankers which are unloaded but remaining or CIP, tankers which are done with CIP but are still in campus, etc.

For detailed report or understanding, kindly read the case-study on RFID System in Dairy Industry.